What Should Be Considered When Using Paving Block Moulds

When it comes to manufacturing high-quality paving blocks, using durable and reliable moulds is crucial. Choosing materials for your moulds, such as ST32 steel and HARDOX steel, plays a significant role in ensuring long-lasting, precise paving blocks. Below are essential factors to consider when using paving block moulds to maximize efficiency and product quality.

1. Material Quality and Durability

The first and most important consideration is the material of the moulds. Paving block moulds made from ST32 steel and HARDOX steel are highly durable, resistant to wear, and able to withstand the repeated pressure of the production process.

- ST32 steel: Known for its good structural properties and affordability, ST32 steel is widely used in the construction industry. It provides the necessary strength and longevity for moulds without inflating production costs.

- HARDOX steel: HARDOX is a high-strength, wear-resistant steel, ideal for moulds that need to endure frequent use in harsh production environments. Its abrasion resistance ensures minimal maintenance and long mould life, even when subjected to heavy loads and abrasive materials.

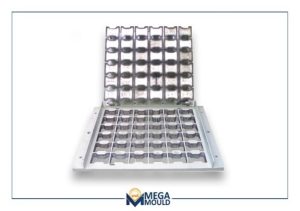

WE ARE USING DIFFERENT METHODS WHILE MANUFACTURING THE STEEL MOULDS

2. Precision in Mould Design

The quality of the paving blocks depends largely on the precision of the moulds. A well-designed mould ensures that each paving block is uniform in size, shape, and quality. Moulds made from HARDOX steel provide exceptional precision, as the material maintains its integrity under stress, allowing for exact replication of design elements.

Consider the following points for mould design:

- Clear edges and corners for precise block shape.

- Smooth surfaces to reduce sticking and ensure easy release of blocks.

- Customization options to meet client needs in terms of shape, size, and decorative patterns.

3. Maintenance and Care

Even the toughest materials require regular care to ensure they last and perform well. To prolong the life of your ST32 and HARDOX steel moulds, follow these maintenance tips:

- Cleaning: After each production cycle, clean the moulds thoroughly to prevent the buildup of concrete residue, which can affect the quality of subsequent blocks.

- Lubrication: Apply the appropriate lubricants to prevent friction during the production process, especially for HARDOX steel moulds, as they endure high-stress conditions.

- Storage: Store moulds in a dry, cool place to avoid rust or material degradation over time. Regular inspections for wear and tear will also help in scheduling timely repairs or replacements.

4. Handling and Setup

Proper handling of your paving block moulds is essential to maintain the structural integrity of both the mould and the paving blocks produced. Given the weight and size of moulds made from ST32 and HARDOX steel, ensure that appropriate handling equipment, such as lifting trolleys or cranes, is used to avoid damage.

- Proper setup: Make sure the moulds are positioned securely on the production machinery to prevent misalignment during the moulding process, which could result in defective blocks.

- Safety measures: Due to the strength of the materials, safety protocols should be followed when moving and adjusting moulds, to protect workers from injuries.

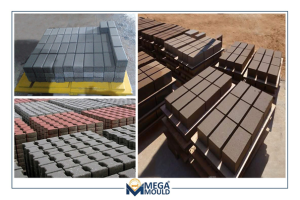

5. Efficiency and Production Output

Your choice of mould material affects not only the quality of the paving blocks but also the efficiency of your production. HARDOX steel moulds, in particular, allow for faster production cycles due to their high resistance to wear and tear. This leads to lower downtime for repairs or replacements and increases overall production output.

For large-scale production, moulds made from these robust steels ensure consistent, high-quality output over a longer period, maximizing profitability.

6. Cost vs. Longevity

While HARDOX steel moulds may have a higher upfront cost than other materials, their longer lifespan and resistance to damage make them a cost-effective investment over time. ST32 steel offers a more affordable alternative while still providing good durability for less intensive production needs.

Depending on the production scale and the specific requirements of your projects, both options provide excellent value for the investment.

Conclusion

When selecting and using paving block moulds, it’s crucial to consider the material, precision, maintenance, and handling. ST32 steel and HARDOX steel offer durability and efficiency, ensuring high-quality paving blocks for every project. By carefully maintaining your moulds and handling them with care, you’ll improve production efficiency and maximize the lifespan of your equipment.

👉Check our blog to learn more about concrete blocks.

📞Contact us for high quality moulds.