Choosing the Best Moulds for Concrete and Paving Block Production

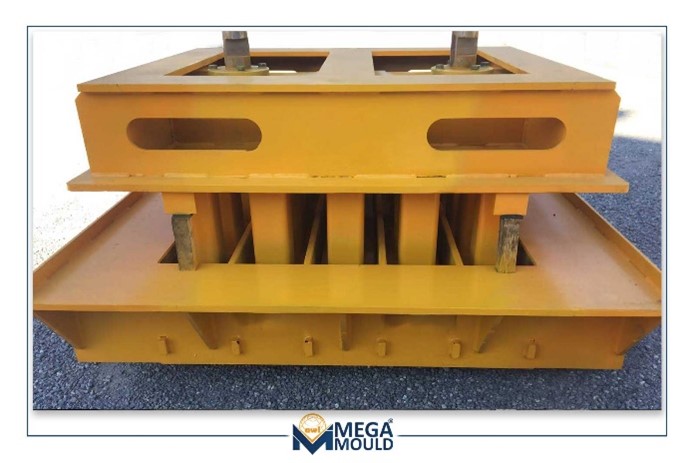

When producing concrete blocks and paving blocks, selecting the right steel mould is key to ensuring product quality and durability. A well-designed mould provides precise shapes and helps extend the lifespan of your equipment, making production more efficient and cost-effective. Below, we’ll explore five essential factors to consider when selecting and maintaining moulds, with a focus on using high-quality materials like HARDOX and ST32 steel.

1. Selecting the Right Mould Model

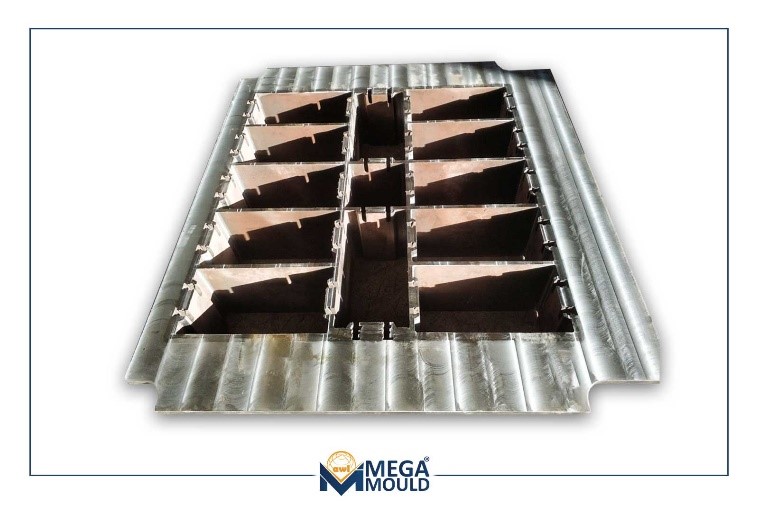

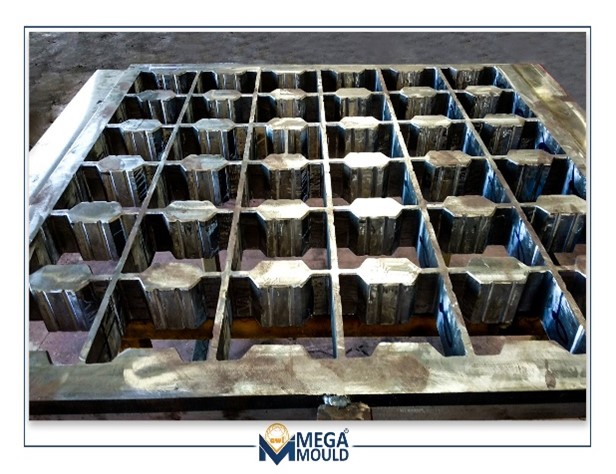

Different markets have varying needs, so it’s important to offer a variety of moulds to meet these demands. Whether you’re producing standard concrete blocks or decorative paving stones, selecting the right model ensures that your products are consistent and high in quality. Having a diverse range of moulds helps you cater to different customer requirements and stay competitive.

Our steel moulds come in various models to support different production goals, ensuring the finished blocks meet both functional and design standards. You can check our steel mould models here.

2. Focusing on Mould Quality

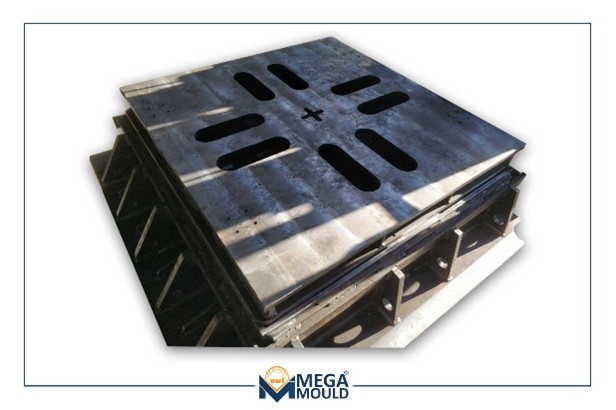

The quality of your mould directly affects the success of your production process. Low-quality moulds tend to wear out faster, which can lead to issues like cracked edges or misshapen blocks, increasing production downtime and waste.

By using HARDOX and ST32 steel, we ensure that our moulds are durable and resistant to wear, helping you maintain consistent block quality throughout the production cycle. This durability is especially crucial for paving blocks, where precise geometric shapes are needed for proper installation.

3. Usability and Efficiency

A productive workflow relies on moulds that are easy to handle. Our moulds are designed with ease of use in mind, simplifying the setup, operation, and removal of the finished blocks. This user-friendly design helps minimize production errors and improves efficiency.

For example, the correct conical angle of the moulds allows blocks to be removed smoothly from the vibrating table, reducing the risk of damage. This is particularly important for decorative paving stones, which require precise shaping for proper fitment.

Check out our blog to learn how to use steel moulds.

4. Importance of Skilled Personnel

Even with high-quality equipment, the experience and skill of your team are crucial to the success of your block production. Properly trained staff can optimize the moulds’ performance, ensuring consistent, high-quality output.

We offer guidance and training to help your team understand how to use our moulds effectively, ensuring that your production process runs smoothly.

5. Regular Maintenance and Cleaning

Proper maintenance is key to extending the lifespan of your moulds. Regular cleaning prevents the build-up of concrete residue, which can affect the mould’s performance and the quality of the blocks. Our moulds are designed for easy cleaning, and we provide maintenance guidelines to help keep them in good working condition.

With the right care, steel moulds made from HARDOX and ST32 steel can last for years, giving you a better return on your investment. Additionally, our moulds come with a guarantee, providing peace of mind regarding their durability.

Boost Your Production with High-Quality Moulds

Choosing the right mould is a critical step in ensuring the success of your concrete and paving block production. With our durable, easy-to-use moulds made from high-quality materials, you can improve efficiency and maintain consistent block quality over time.

In conclusion, investing in durable, easy-to-use steel moulds not only boosts the quality of your concrete and paving blocks but also enhances your production’s overall efficiency.

The combination of long-lasting materials, flexibility in mould design, and easy maintenance ensures that your business stays productive and profitable for years to come.

Whether you’re producing simple concrete blocks or high-end decorative paving stones, our steel moulds provide the foundation for reliable and consistent production.