What Should Be Considered When Using Paving Block Moulds?

Content

1- Finding the Right Model For You

2- Installation of The Mould

3- Changing The Machine Moulds

4- Avoiding Over or Under-Use of Raw Materials

5- Choosing The Right Pallet

6- Operator Knowledge and Experience

7-Cleaning and Maintenance of The Moulds

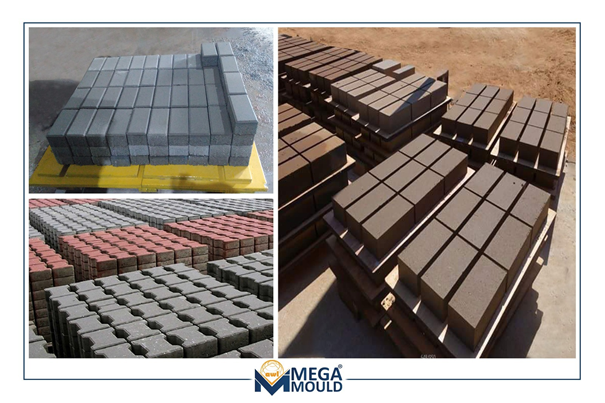

1-) Finding the Right Model For You

First of all, remember the principle of demand and supply. When buying new moulds, ask yourself: What exactly do you want in paving blocks? Do you want a model to be used on its own? Or do you want more complex patterns? What are the most popular models in your country or city? You should choose a mould that fits your goals and your customers' wishes.

It is one of the 1st principles valid for every production and you have to determine the models which are on high demands in the paving industry by the customers. You can make more profitable business decisions with a correct choice of paving block model production.

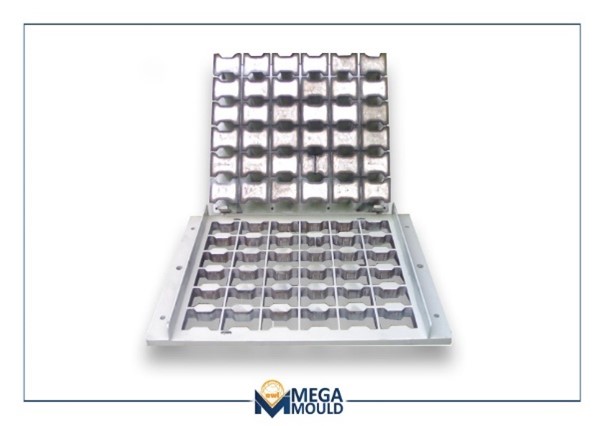

2-) Installation of The Mould

The correct installation of paving block mould on the paving block machine ensures the healthy operation of the whole machine. Problems that will occur during the installation phase may cause the machine to malfunction or damage the existing mould and cause defective products. That's why it's best to work with people who are familiar with your machine model and joints!

We make sure that the joints of the mould are carefully connected. Special attention should be paid to situations such as a screw being loose or a screw being too tight. Incorrect installation of the mortar buckets on the machines may damage the mould during its movement on the mould.

By paying attention to such details, we will extend the life of your moulds and machines.

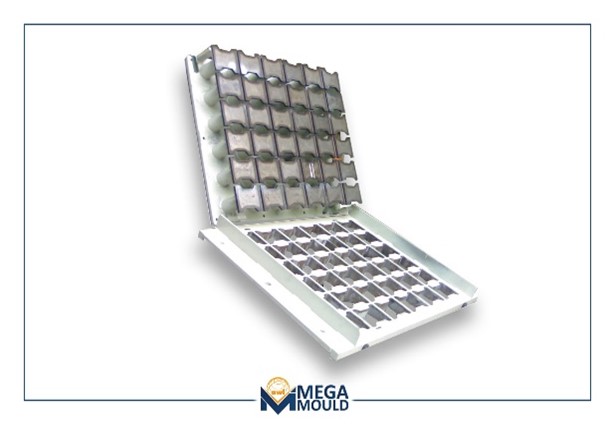

3-) Changing The Machine Moulds

You may need to change the paving block mould according to the production in progress or the orders received. During the replacement process, the mould must be removed and the installation of the new mould must be done correctly.

The mould settings and balance may be disturbed in case of a wrong installation process. Therefore, the products may be damaged or the mould may become completely unusable.

During daily production, the operator must be constantly checking the moulds against the possibility of the screws getting loose.

4-) Avoiding Over or Under-Use of Raw Materials

The recommended amount and size of raw materials for the machines should be used correctly. It is an undeniable fact that the use of incomplete or excessive raw materials will both cause damage to the mould and results to inaccurate production.

The type of raw materials used should also be considered during the selection of the moulds. This is because, if the structure of raw material chosen is harder than the mould’s raw material, the life-span of the moulds will be affected negatively. The raw materials used and the hardness of the mould’s structure should be proportion matched.

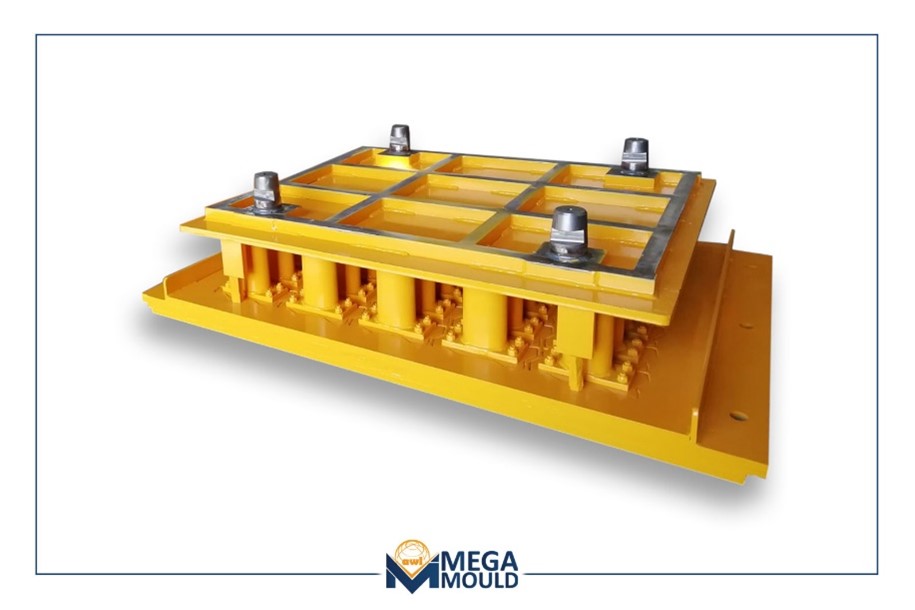

5-) Choosing The Right Pallet

Care should be taken to use the recommended pallets dimensions for the machines.

If the pallet used are not suitable one the machines, the machines and most of the products will be damaged.

6-) Operator Knowledge and Experience

One of the most important factors in machine and mould usage is the knowledge and experience of the operators. If the operator does not have enough knowledge and experience, both the machine and the moulds will not be welled managed this will lead to production errors and loses in business.

During production, the operator must constantly make the necessary checks. Because unwanted objects may escape into the mould and seriously damage both the mould and the products.

7-) Cleaning and Maintenance of The Moulds

All the necessary maintenance of the machines should be done regularly and periodically. Cleaning of the mould should be done carefully by the operator at the end of each job. Thus, the moulds will be made ready for new production.

Since the materials in the mould freezes after a certain amount of time, this causes the mould to wear and the products produced are damaged.

Click to view the high-quality paving blocks mould models we produce with the latest technologies.

Also take a look at this article on how to buy a good paving block mould (https://megamoulds.com/article/what-should-be-considered-when-buying-concrete-block-and-paving-block-moulds/21)